Thickness Gauges & UT Instruments

Dakota Ultrasonics

Proudly Supplied by RSL NDT

Dakota Ultrasonics provides dependable and accurate ultrasonic thickness measurement solutions for corrosion monitoring and structural assessment.

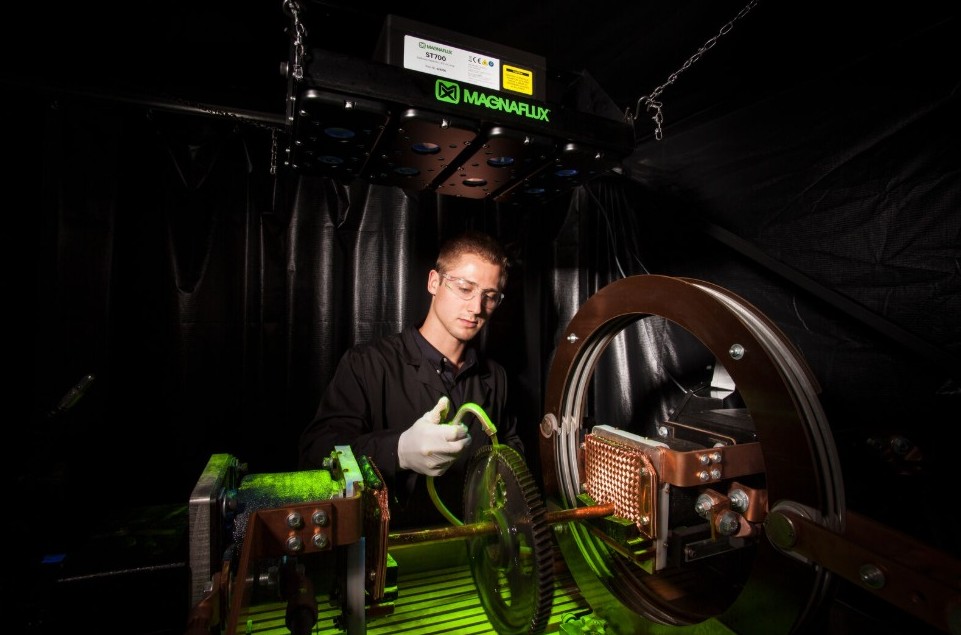

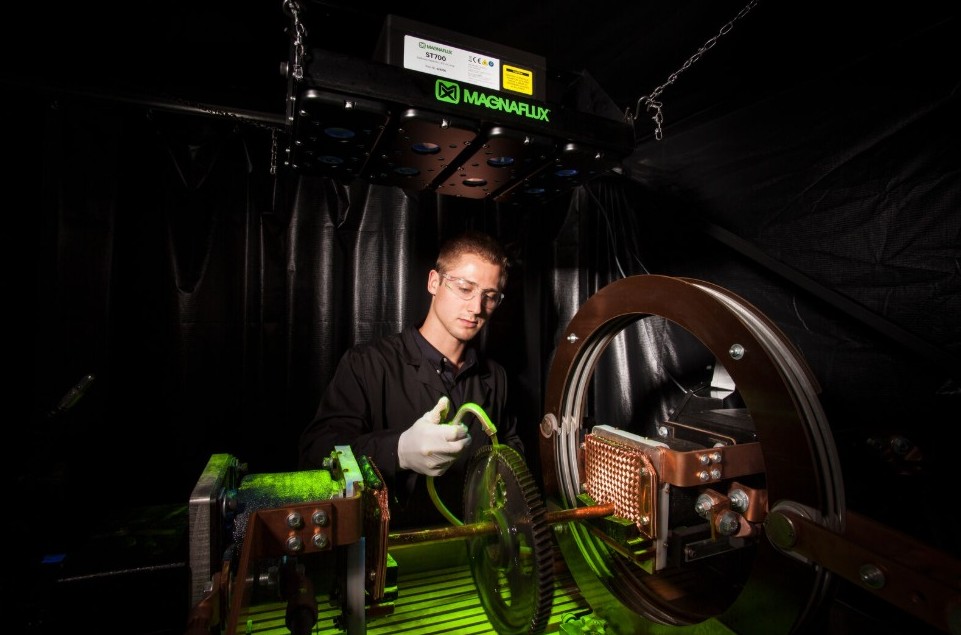

Magnaflux

Magnaflux is one of the most trusted and recognisable names in Non-Destructive Testing, known for producing consistent and repeatable MT and PT materials that help inspectors identify surface-breaking defects with clarity and confidence. For decades, Magnaflux chemistries and equipment have been used by teams working in demanding production and maintenance environments where the reliability of the inspection process is critical. Their product families are designed to simplify inspection, improve quality control, and integrate smoothly into both manual and automated workflows.

What We Offer Through RSL NDT

RSL NDT supplies a wide selection of Magnaflux consumables and equipment, supporting both workshop-based inspection and mobile, onsite operations. Our focus is on materials that are proven, industry-accepted, and supported by comprehensive documentation. Whether you’re performing routine quality checks or carrying out sensitive aerospace-level inspections, our Magnaflux range ensures robust performance and process consistency.

Includes fluorescent and colour-contrast penetrants, emulsifiers, removers, and various developer formats designed to enhance flaw visibility.

Such as powders, suspensions, contrast paints, and carrier fluids suitable for a wide range of magnetic techniques.

Across handheld and fixed configurations to support reliable MT and PT visual evaluation.

Includes portable yokes, bench units, and a variety of accessories and indicators used to verify and maintain inspection quality.

Such as tam panels, ketos rings, centrifuge tubes and hydrometers to ensure compliance with relevant standards.

Aerospace

Automotive

Oil & Gas

Fabrication

Rail

Power Generation

General Manufacturing

helping operators maintain confidence in component safety and integrity.

Why Source Magnaflux from RSL NDT?

Choosing Magnaflux through RSL NDT ensures an authorised, reliable supply supported by a full SDS/TDS library and the guidance of NDT specialists who understand how these consumables and tools perform in real-world applications. We maintain consistent stock levels, offer fast UK dispatch, and support customers with technical insight to help them select the correct materials for their inspection process.

Dakota Ultrasonics

Dakota Ultrasonics is known for producing rugged, easy-to-use UT instrumentation designed for real-world industrial inspection. Their gauges are widely used to evaluate corrosion in pipelines and vessels, measure precision components in manufacturing environments, and support structural assessment in transport and marine sectors. The emphasis on measurement stability, user-friendly interfaces, and durable construction makes Dakota a dependable choice for both routine and advanced inspection tasks.

What We Offer Through RSL NDT

RSL NDT supplies a streamlined range of Dakota thickness gauges, probes, and accessories, ensuring that operators can select the right tool for their application—whether that involves precise thin-material measurement or assessing corrosion in heavy-wall structures. We also provide calibration blocks and accessories to support correct instrument setup and verification.

For corrosion, precision, and multi-mode measurement.

Designed for fine-tolerance inspection.

Includes single-element, dual-element, and application-specific configurations.

For stable measurements.

To support gauge setup and verification.

Oil & Gas

Marine

Utilities

Transport

Fabrication

Manufacturing

supporting both in-service inspection and production control.

Why Source Dakota from RSL NDT?

With RSL NDT, customers benefit from expert advice on selecting the correct gauge for their application, along with support for calibration, certification, and accessories. We offer rapid delivery, competitive availability, and guidance to help inspectors achieve consistent and accurate measurements.